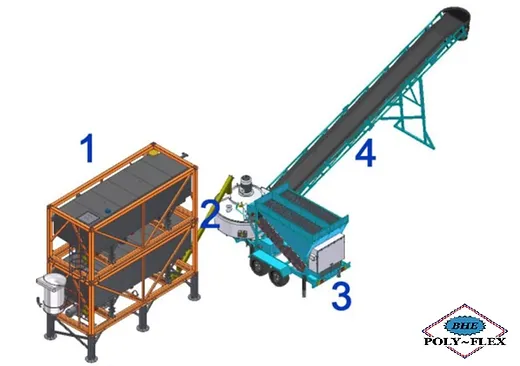

Mobile Batch Plants Convenient with Instant Availability

Here are some ideal additions to your business which are suitable for:

• Small & Medium sized concrete contractors who want control over their supply and quality

• Contractors who want the ability to react immediately to customer needs without having to book concrete weeks in advance

• Sand, soil and garden centres who want to supply that extra “Mini-mix” service to customers

• Regional businesses who want to provide a unique “Mix on site” service.