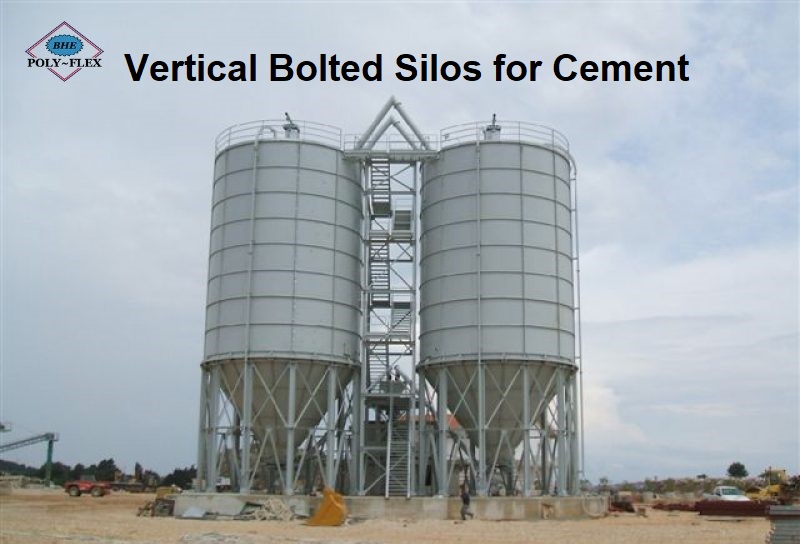

Throughout Australia, vertical bolted silos have emerged as an indispensable part of the cement and construction storage industry. With every new development in the construction landscape, more space-efficient ways of storing cement and various other construction materials will be required. One company that manufactures high-quality vertical bolted silos is Batch & Reclaim – Bulk Handling Equipment and they provide strong, flexible and affordable solutions that specifically meet the demands of the Australian construction industry.

What reality does Vertical Bolted Silos facilitate?

Vertical bolted silos are cylindrical designs which pack, store, and distribute bulk materials such as cement in a safe and effective manner. Construction of vertical bolted silos is done at the site using pre-fabricated modular panels that are bolted together. Vertical silos have wide applications in construction, mining, and manufacturing due to flexibility and ease of installation, which also enhances its life span.

Knowing the Key Characteristics of Vertical Bolted Silos:

- Modular Design – Prefabricated panels allow these silos to be easily transported and put together at the location.

- Durability – Bolted silos have a highly durable life span as they are built from strong steel structures to withstand tough Australian climatic conditions.

- Capacity Options – These products are offered in different storage capacities, the smallest suitable for small-scale works while the largest can function as a bulk storage silo.

- Versatility – Ideal for the storage of cement, fly ash, aggregates, and any other construction material in bulk.

- Customizable – The structures can be tailored to individual site requirements as well as offer additional features such as liners, aeration systems, and discharge mechanisms.

Importance of Vertical Bolted Silos in Australia

The growth rate of the construction industry in Australia has been on the rise owing to the expansion of infrastructure and urban development. For these projects to be successful, there is a dire need for tools that will adequately store the bulk materials efficiently, cement being one of them. The introduction of vertical bolted silos has enhanced the overall efficiency and productivity of construction works in a number of ways.

- Efficient Storage and Handling of Cement

B&R-BHE’s silos are provided with aeration systems to eliminate bridging of materials, ensuring a uniform flow of cement during dispensing.

- Sturdiness and Robustness

Construction sites in Australia generally have harsh temperatures, excessive dust, and moisture contact. The vertical bolted silos of B&R-BHE are manufactured by using high-strength steel that provides anti-corrosion, anti-weathering and anti-mechanical wear properties. This strength provides a certainty of performance for a longer period of time hence cutting down the cost of maintenance and increasing the length of the silo operation.

- Space Efficient Design

Urban Australia does not have unlimited land space and with the use of vertical silos, land can be used efficiently. The storage capacity in confined areas is enabled by the use of their vertical structure as it takes up a lesser floor area compared to regular silos. Urban construction sites can greatly benefit from the compact design as space is always a concern. The vertical silos require lesser space for setup.

- Economic and Fast to Install

Their modular structure makes vertical bolted silos inexpensive and further makes installation easier leading to decreased costs. Because the panels are cad-cam designed and laser cut beforehand, it enables easy and quick setting hence saving on the construction time and labour. B&R-BHE offers complete services, enabling rapid installation of silos, which minimizes waiting time and makes project schedules smoother.

Batch & Reclaim – Bulk Handling Equipment: Top Brand in Vertical Bolted Silos

In Australia, B&R-BHE is a well-known supplier of Vertical Bolted Silos for Cement and other bulk materials storage. Intelligence related to bulk storage, therefore, allows the construction to be done in a much more effective way and increases its productivity.

Why go with BulkHandlingEquipment?

- A Huge Variety of Silos – BulkHandlingEquipment has an assortment of vertical bolted silos which range from the smallest size to the largest needed in various constructions such as small and large-scale infrastructural projects.

- Custom Made Designs – The company gives the option of customization such as the size and capacity of the silos and also extra equipment such as ladders, discharge systems, safety systems etc.

- High-Quality Equipment – BulkHandlingEquipment makes sure that its silos have high-strength materiel composition and eye magnet designs that can withstand extreme conditions while providing long-term performance.

- Professional Assistance – The company also provides installation supervision and technical maintenance advice and stays with the company for assistance for the whole life cycle of silos.

Conclusion

The Australian construction industry finds vertical bolted silos important in large-scale basements and other constructions for the easy storing of cement and other raw materials. Because the vertical bolted silos provided by BulkHandlingEquipment will last long, be efficient while also being cheap and easy to use, it means that there is an increasing demand in construction. By purchasing vertical silos of high quality, civil engineering and other construction companies are paving the way for smooth transitions in their operations.